Create an Industry-leading

Manufacturer of Premium Quality

SPA Hot Tub

Manufacturer of Premium Quality

SPA Hot Tub

Views: 0 Author: JOYEE-Evelyn Publish Time: 2025-10-31 Origin: Site

JOYEE SPA has established a state-of-the-art intelligent production line designed to deliver consistent quality across all spa and hot tub manufacturing processes. From acrylic forming and spraying to drilling, flipping, and water testing, every step is automated to achieve maximum efficiency, precision, and safety. With a 50,000㎡ modern factory and 73% of the production line fully automated, JOYEE SPA provides world-class OEM & ODM solutions to international brands.

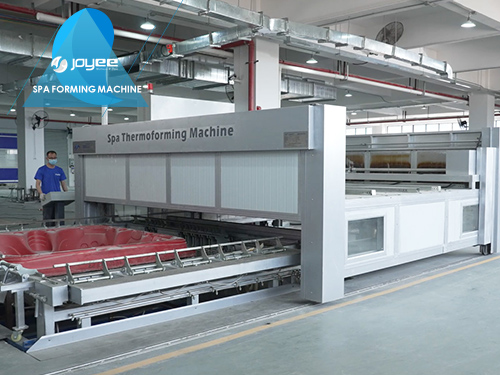

The Spa Vacuum Forming Machine is the primary automated equipment for shaping spa shells with uniform thickness and smooth surfaces.

Using a high-temperature heating system, acrylic sheets are softened and vacuum-formed onto molds in a single-step process. Intelligent temperature controls and automated forming programs adjust heating duration, temperature, and vacuum pressure for different models, while automatic cooling and demolding reduce human intervention.

This ensures shells with stable structures ready for further processing.

The Spa Spraying Machine applies a uniform layer of resin and fiberglass on the back of spa shells to reinforce structural strength.

Automated control ensures consistent coating thickness and adhesion, while enclosed chambers and self-cleaning systems improve worker safety and production cleanliness.

Compared with manual spraying, this system reduces human error, optimizes efficiency, and ensures every spa meets high-quality standards.

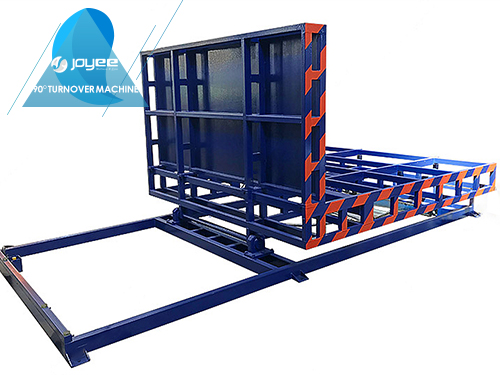

Designed for large spa shells, the 90° Turnover Machine allows precise and controlled 90-degree rotation. Powered by electric or hydraulic systems, it simplifies operations like spraying, polishing, piping, and inspection.

Automated control minimizes manual handling, prevents product damage, and connects multiple production stages, improving efficiency and maintaining shell integrity.

The YASKAWA Drilling Robot delivers fully automated, high-accuracy drilling for jets, valves, and control panels. Utilizing CNC control and vision-assisted positioning, it achieves micron-level precision, eliminating manual errors.

The system automatically selects, replaces, and calibrates drill bits, while servo arms adjust to curved surfaces.

Continuous operation with minimal supervision reduces labor costs, enhances safety, and ensures consistent drilling quality.

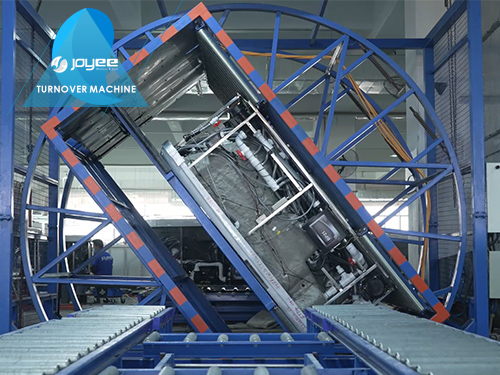

After water testing, the Automatic Turnover Machine efficiently drains the spa pool using intelligent control.

Compared with manual draining, it provides faster, safer, and standardized operation, minimizing labor and ensuring a seamless transition to inspection and packaging.

These advanced machines form the backbone of JOYEE SPA’s automated production line, guaranteeing precision, safety, and efficiency. With 73% automation and a 50,000㎡ factory,JOYEE SPA is capable of large-scale, high-quality OEM production. As a trusted Top OEM & ODM partner, JOYEE delivers tailored spa and hot tub solutions for international clients, combining craftsmanship and advanced technology to produce market-ready premium products.

Create an industry-leading manufacturer of premium quality SPA hot tub